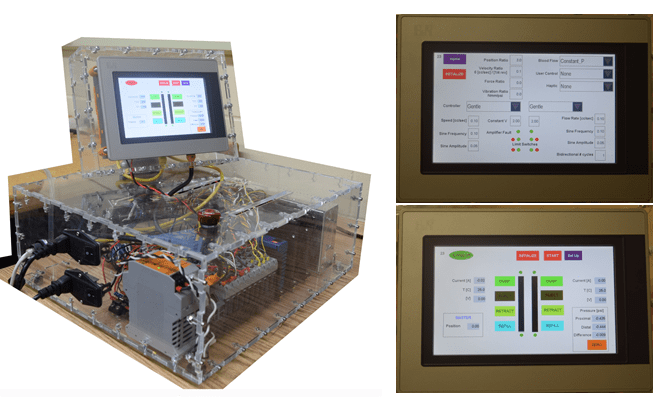

Motivation: Angiographic power injectors are commonly used in interventional radiology to introduce a contrast media into vascular structures. Commercially available power injectors are capable of injecting at fixed flow rates. However, power injectors are not widely applied in neuroradiology due to the concern with excessive pressure that could cause aneurysm rupture. Previous work in teleoperated medical interventions has shown that haptic feedback provided to clinicians could enhance safety and improve user performances. Inspired from these successes, we developed a bilateral teleoperated power injection system. With the haptic feedback, clinicians will be able to sense the injection pressure, detect abnormal issues to avoid damaging vascular tissues, while leveraging the power injector to inject at high flow rates.

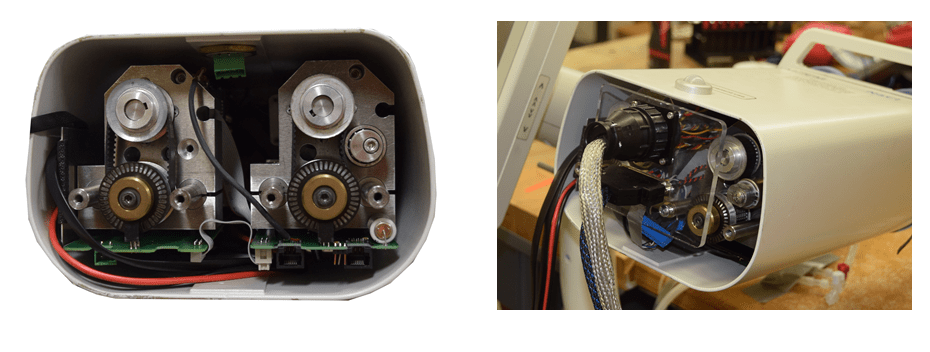

I reformed this power injector by removing the built-in electronics while keeping the mechanical components, including the motors and the lead-screw mechanism. I added external brushless DC motor controller and custom electronics to make it a teleoperation system.

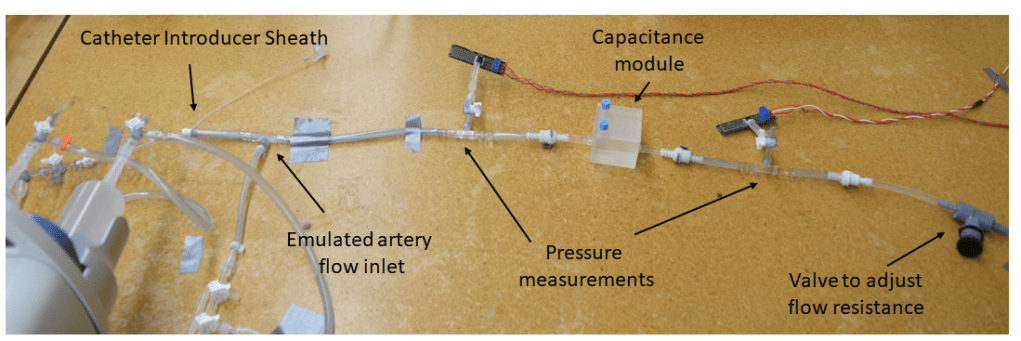

I built an in-vitro testbed that emulates the process of injection into Common Carotid Artery.

I used Windkessel model, a lumped parameter hemodynamic modeling approach. I gained inspiration from this article to mimic the behavior of CCA by building the capacitance module. I am working on getting more laminar flow and linear flow resistances.

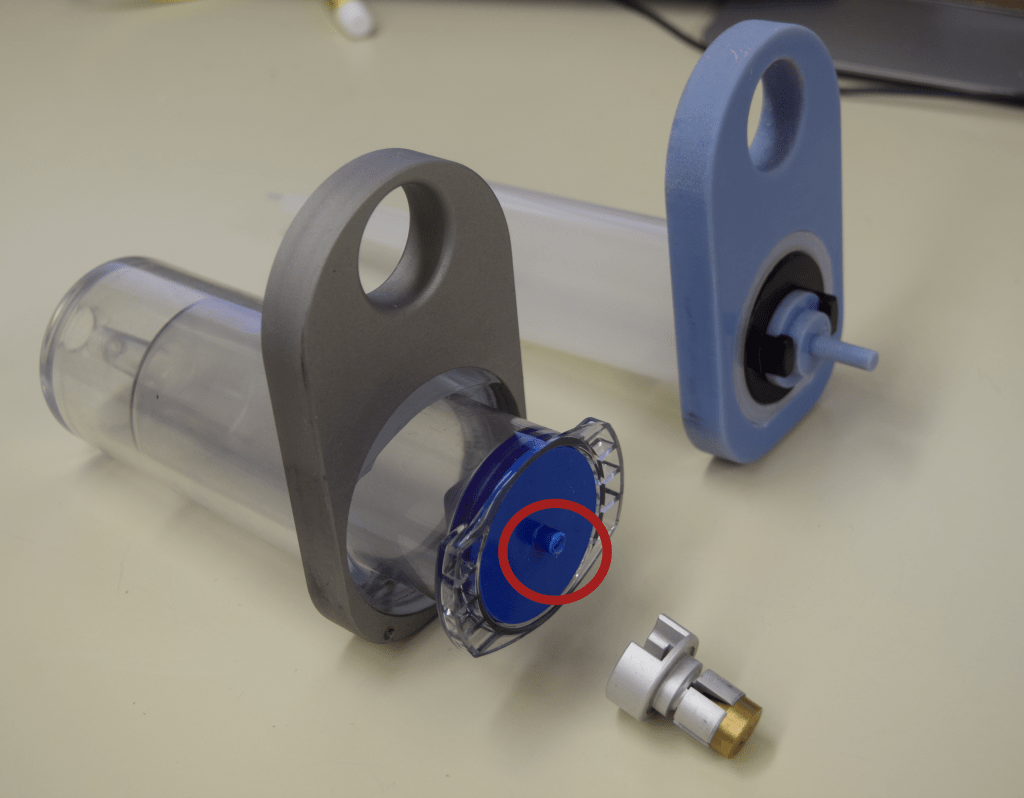

One challenge I encountered was that the syringes for medical applications are usually designed for one-time use. See the shoulder at the end of the piston broke after repetitive testing, circled in red. Especially the syringe for the injector has been obsolete for more than a decade. To solve this challenge, I redesigned the fixture for up-to-date syringes. By leverage a transtorque bushing, I was able to install my redesigned fixture to the lead-screw mechanism.